C3

Interaction of heat transfer, drying and thermochemical processes in a hearth furnace floor

C3 delivers experimental data sets which allow to verify DEM/CFD simulations and is, therefore, a key element in the CRC/TRR’s validation strategy. Two test rigs (a generic grate system and a generic hearth furnace configuration) are used to generate a unique data set on particle mechanics for agitated granular assemblies. Extended research on thermochemistry, namely pyrolysis and char conversion of wood particles, is conducted on a reacting grate.

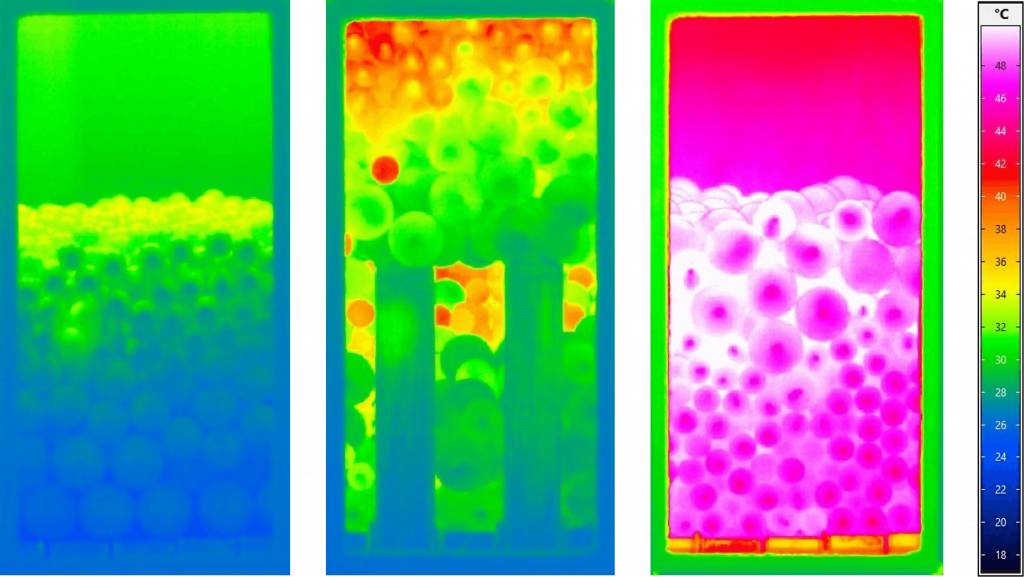

The grate system provides a comprehensive data for particle mechanics and convective heat transfer for polydisperse moving granular assemblies with gas flow. The particle bed is agitated by moving grate bars which allow for different bar moving modes. Mixing and segregation of complex-shaped but regular polyhedral particles can be studied through optically transparent test rig side walls. The moving granular assembly is exposed to a passing flow of hot air. Particle temperatures are obtained by infrared camera recording. In addition, the test rig serves as a test bed for measurement of particle trajectories by Positron Emission Particle Tracking (project C1) and Radar Wave based tracking (project B1).

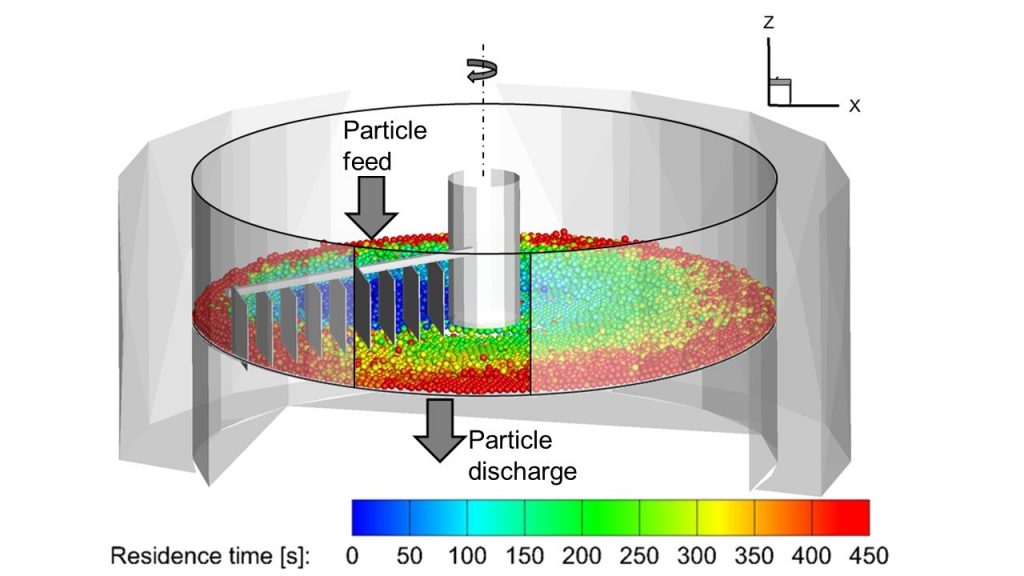

In the hearth furnace configuration, particles located on the circular furnace floor are agitated by a rotating rabble arm which is equipped with mixing blades. The furnace floor is heated electrically which allows to study contact heat transfer. Also here, particle temperature and particle trajectories are determined for spherical and polyhedral geometries of different sizes and materials.

In the reacting grate system, the particle bed is heated by radiation and contact heat transfer and in parallel cooled by a gas flow. The test rig consists of a cylindrical burner bowl containing the fuel bed and a cylindrical gas phase combustion chamber. Optical and gas sampling measurements enable the characterization of the ongoing thermochemical processes. The two main phases of biomass combustion, pyrolysis and char conversion, will be examined separately. This separate analysis of pyrolysis and char conversion provides well-defined data sets for DEM/CFD validation not available today.

The goal of project C3 is to generate a full set of input parameters of particle mechanics, thermal and chemical behaviour for DEM/CFD simulations in project C7.