B4

Adaptive pore network modelling of thermochemical processes in single porous particles

A crucial component in the development of DEM/CFD computational tools to describe the thermochemical behaviour of bulk solids are the single particle models for DEM. Only with accurate single particle models, particle conversion and/or particle product qualities can be reliably predicted at the outlet of industrial reactors. The complexity in the description lies in the fact that at particle scale chemistry and transport compete at similar time scales.

Project B4 is driving the advancement in the modelling of reactive processes at particle level, with a primary focus on biomass pyrolysis and char conversion as model reactive systems in FP2. Biomass conversion has been selected as it can serve as a highly complex model system for DEM single particle models including heterogeneous reactions, change of particle shape and pore structure, as well as anisotropic intra-particle transport properties. As methodological approach to develop sophisticated single particle models, a novel, one-of-a-kind simulative-experimental framework will be derived. This framework will be sustained on three pillars: the development of adaptive pore network models (PNM), the parametrisation of continuum models (CM) based on effective transport, chemical, and morphological properties derived from the highly resolved PNM simulations, and the provision of measurement data that facilitate the bridging of scales from PNM to CM.

A single porous particle is represented by an idealized network of cylindrical throats interconnected to spherical pores. The drying kinetics and the size evolution of the particle’s pores and throats during the drying process are visualized.

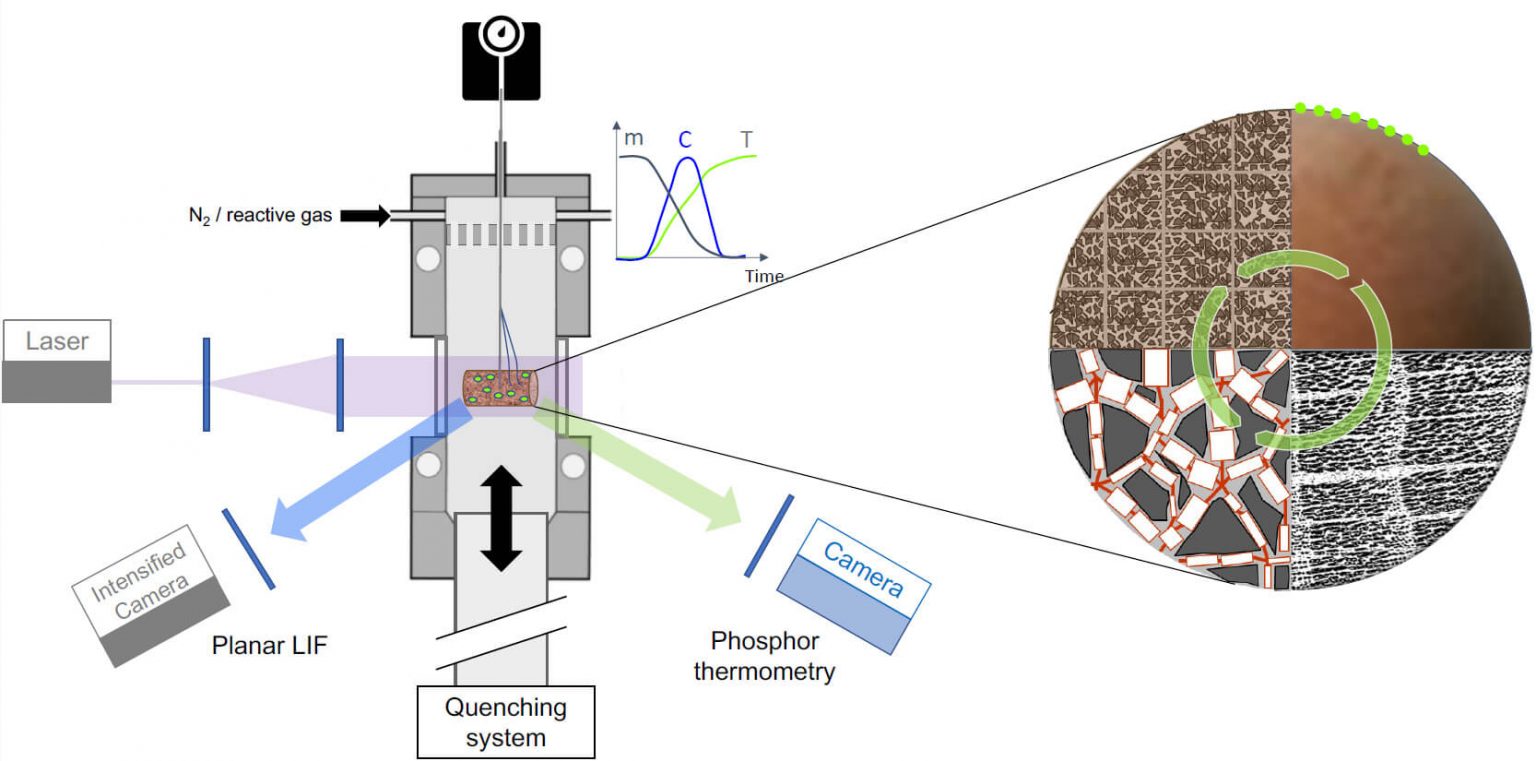

The adaptive pore network models will address the dynamics of the change of particle morphology and microstructure, intra-particle heat and mass transport, and chemical reactions. In parallel, a unique set of experimental data will be provided, generated from measurements inside a novel single-particle reactor. The measurement methods applied will combine information on intrinsic kinetics and intra-particle and extra-particle transport processes. To characterize intra-particle processes, thermogravimetry, probe-based infrared spectroscopy (FTIR) measurements, and different methods to assess change of pore structure as a function of reaction progress will be applied. To retrieve information from the particle surface, phosphor thermometry will be used. Finally, to close the gap to the gas-phase boundary layer two-dimensional laser-induced fluorescence (2D-LIF) spectroscopy will be refined to deliver the species concentration profile around the particle. Only this combination of detailed PNM models and comprehensive experimental data will allow for the development and validation of 3D particle continuum models (CM) that go beyond the state of the art. These validated (full-order) CM models will be incorporated into the DEM/CFD framework by C7. C4 will reduce the full-order CM models to speed up simulations. Together, B4, C4, and C7 will evaluate the performance of the different single particle models at system level.

The pore network modeling and simulation of the calcination process of a single limestone particle. The movie provides detail insights into the transformation of the limestone into an active lime during the conversion process.